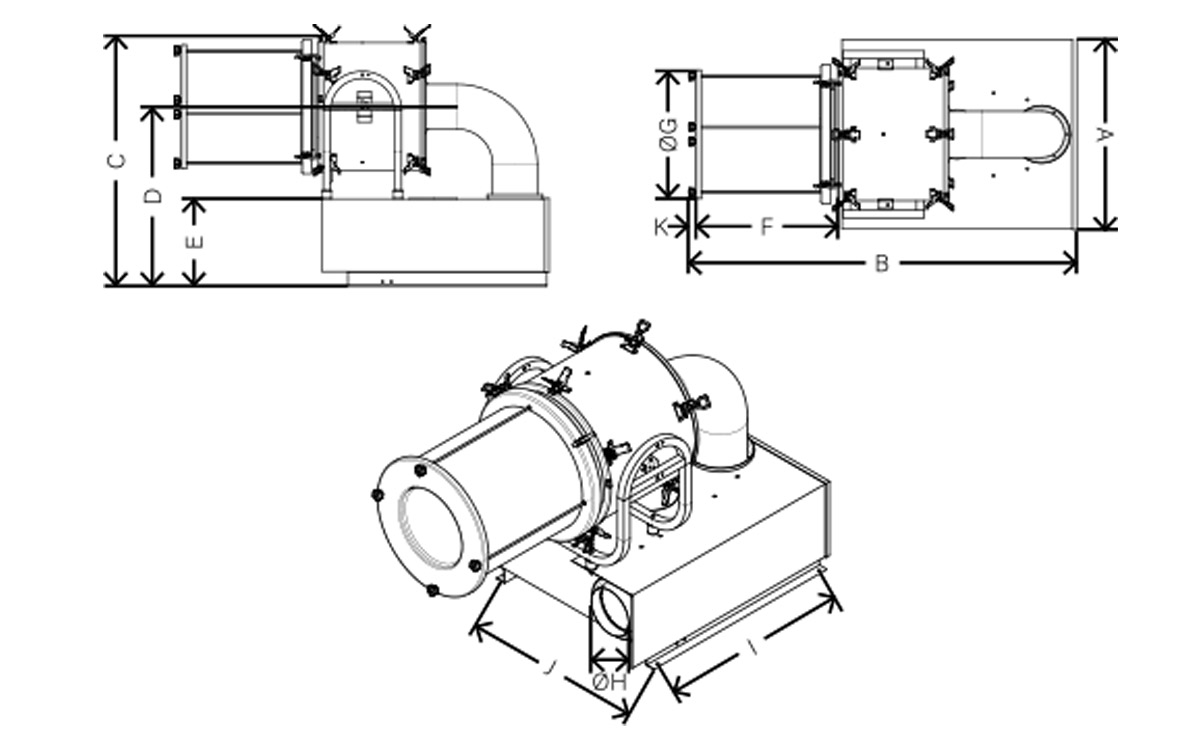

Centrifugal Fan Unit for mists and fumes.

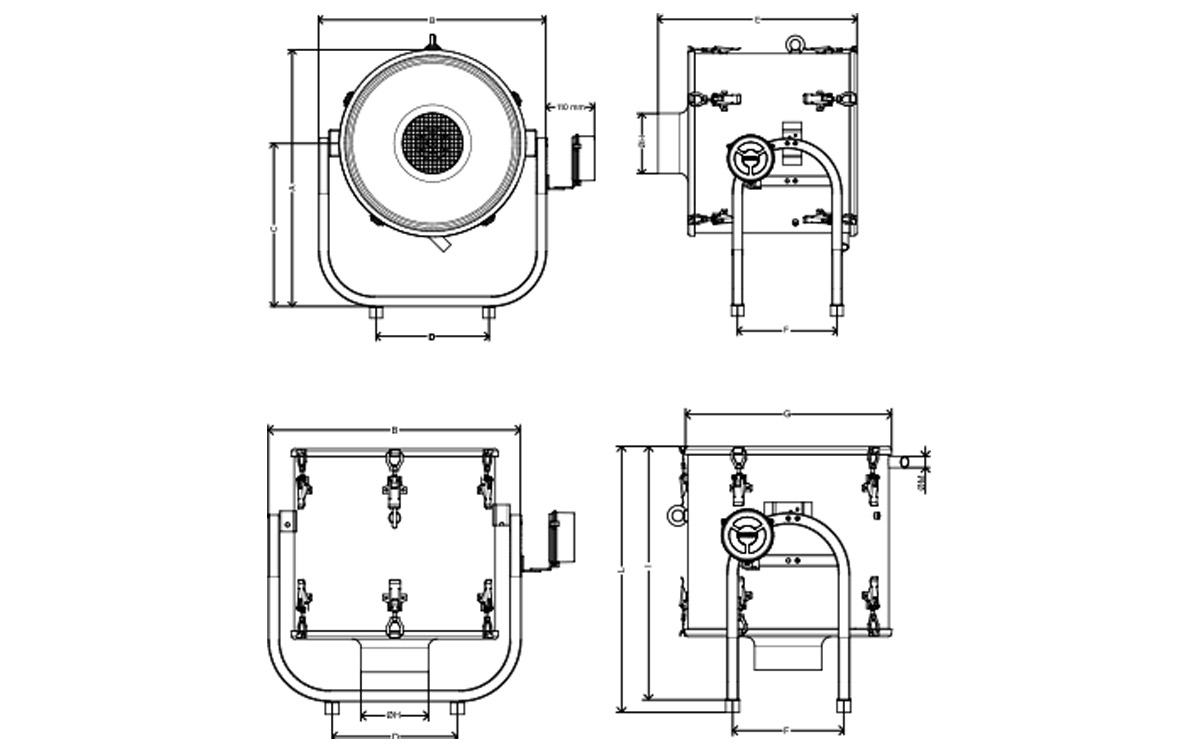

The Darwin series is a line of centrifugal filters for the purification of air containing oily mists, micro-mists and fumes resulting from the use of coolants (emulsion or neat oil).

It can be used on all types of machine tools and for all removal operations.

It is available in 4 sizes with 3 different fully interchangeable filtration technologies. Available flow rates range from 600 to 3,000 m3/h, with various combinations of increasing filtration efficiency, up to an efficiency of 99.97%.

Patented in the USA and Europe (Italy, France, Germany, Great Britain, Luxembourg, Switzerland, Sweden, Spain).

Losma guarantees that each filter unit is individually tested through rigorous control procedures. A quality and functional test certificate is issued for each unit.

TR

TR  EN

EN